Types and Features of 165-Degree Kitchen Cabinet Hinges: Kitchen Cabinet Door Hinges 165 Degree

Choosing the right hinges is crucial for both the functionality and aesthetic appeal of your kitchen cabinets. 165-degree hinges offer a significant advantage over their less-angulated counterparts, allowing for a nearly full-overlay door style while maintaining smooth operation. This section delves into the various types and features of these specialized hinges.

Types of 165-Degree Kitchen Cabinet Hinges, Kitchen cabinet door hinges 165 degree

165-degree hinges cater to different cabinet styles. The primary distinctions lie in how the door sits in relation to the cabinet frame: full overlay, inset, and half overlay. Full overlay hinges completely cover the cabinet face frame, creating a sleek, modern look. Inset hinges position the door within the frame, offering a more traditional, often more expensive, aesthetic. Half overlay hinges partially cover the frame, presenting a compromise between the two.

Comparison of 165-Degree Hinge Features

The following table compares common features across these hinge types. Note that variations exist within each category based on brand and specific model.

| Type | Material | Mounting Style | Durability |

|---|---|---|---|

| Full Overlay | Steel, Nickel, Zinc Alloy | Screw-on, Clip-on | High; withstands frequent use |

| Inset | Steel, Brass | Screw-on, often with adjustable mounting plates | High; requires precise installation for optimal performance |

| Half Overlay | Steel, Zinc Alloy | Screw-on | Moderate to High; balance between cost and functionality |

Advantages and Disadvantages of 165-Degree Hinges

Using 165-degree hinges offers a wider opening angle compared to 110-degree hinges, providing easier access to cabinet contents. This is especially beneficial for corner cabinets or those with deep shelves. However, the increased angle might require more precise installation to ensure proper door alignment and prevent interference with adjacent cabinets. Conversely, 110-degree hinges, while less revealing, offer a simpler installation process and are often less expensive.

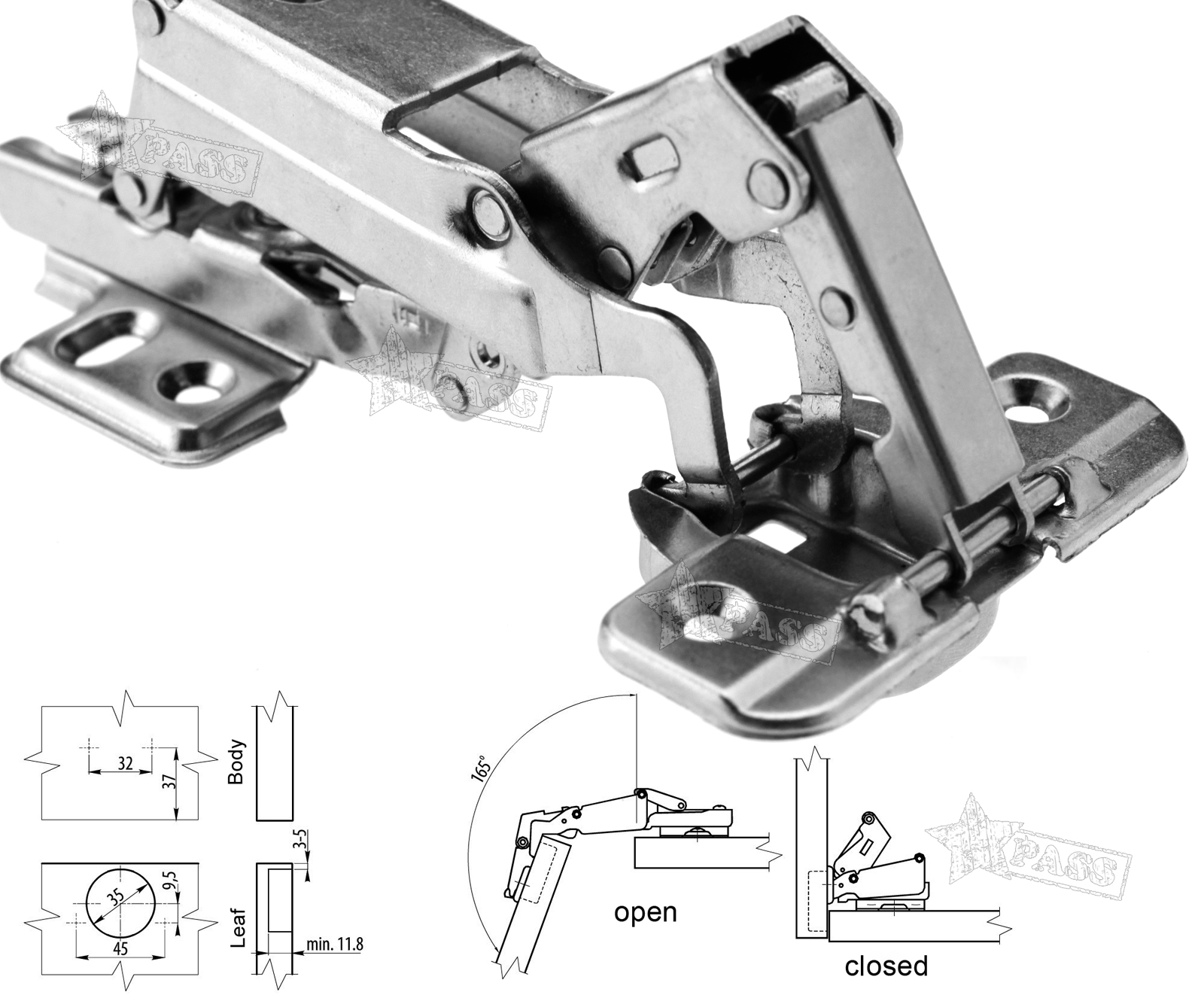

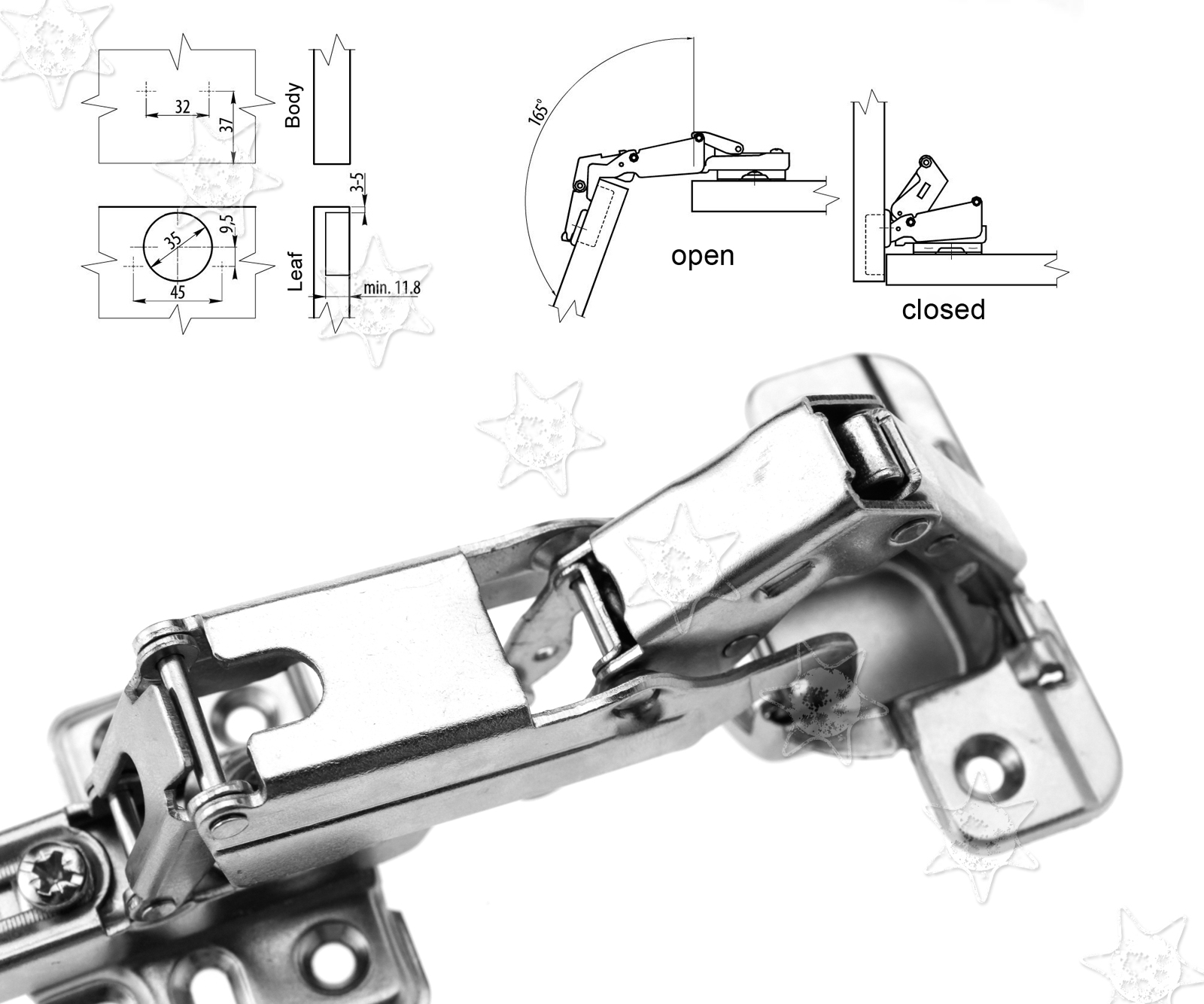

Installation of a Full Overlay 165-Degree Hinge

The following steps Artikel the installation of a typical full overlay 165-degree hinge. Always refer to the manufacturer’s instructions for your specific hinge model.

Kitchen cabinet door hinges 165 degree – Precise installation is key for optimal performance and a seamless look. Take your time and double-check measurements before securing any screws.

- Step 1: Locate Hinge Placement: Determine the hinge placement on the cabinet door and frame using a template or careful measurements. Maintain consistent spacing between hinges for balanced door operation.

- Step 2: Attach the Hinge Cup to the Door: Use a drill to create pilot holes, then attach the hinge cup to the inside of the cabinet door using the provided screws. Ensure the cup is flush with the door surface.

- Step 3: Attach the Hinge Plate to the Cabinet Frame: Attach the hinge plate to the cabinet frame using screws. Ensure the plate is aligned correctly with the hinge cup for smooth operation.

- Step 4: Adjust the Hinge: Adjust the hinge screws to fine-tune the door’s alignment and ensure a smooth, gapless closure. This may involve slight adjustments to the hinge cup’s position or the plate’s placement.

- Step 5: Repeat for Remaining Hinges: Repeat steps 1-4 for all hinges on the cabinet door.

Cabinet Door Appearance and Functionality with Varying Hinge Angles

A 110-degree hinge results in a cabinet door that opens only partially, leaving a significant portion of the cabinet face frame visible. This is typical for overlay and partial overlay cabinet styles. In contrast, a 165-degree hinge allows for a near-full-overlay style, where the door almost completely covers the frame, creating a clean, modern look. The increased opening angle with the 165-degree hinge significantly improves accessibility, particularly for deep cabinets or corner units. The visual difference is striking: a more contemporary, streamlined appearance with the 165-degree option versus a more traditional look with the 110-degree hinge.

Choosing the Right 165-Degree Hinge for Your Kitchen Cabinets

Selecting the perfect 165-degree hinge for your kitchen cabinets involves careful consideration of several factors. The right hinge ensures smooth operation, lasting durability, and a professional finish. Ignoring these factors can lead to frustrating cabinet malfunctions and premature wear.

Comparison of 165-Degree Hinge Brands and Manufacturers

Choosing between different brands and manufacturers requires understanding the nuances of quality and price. Higher-priced hinges often offer superior materials, smoother operation, and longer lifespans. However, budget-friendly options can still provide acceptable performance for less demanding applications. The following table compares some popular brands, offering a snapshot of their offerings. Note that pricing can fluctuate based on retailer and specific model.

| Brand | Model (Example) | Price Range (USD) | Key Features |

|---|---|---|---|

| Blum | Blum Aventos HF | $15 – $40 | Soft-close mechanism, durable construction, wide range of sizes and finishes, excellent reputation for quality. |

| Hafele | Hafele Grass Tiomos | $10 – $30 | Variety of styles and finishes, known for reliable performance, generally good value for money. |

| Salice | Salice 165 Degree Hinge | $8 – $25 | Strong and durable, often used in heavier cabinets, offers a good balance between price and quality. |

| Liberty | Liberty 165 Degree Hinge | $5 – $15 | More budget-friendly option, suitable for lighter cabinets and less frequent use, may not offer the same longevity as premium brands. |

Hinge Selection Based on Cabinet Door Weight, Material, and Functionality

The weight of your cabinet door significantly impacts hinge selection. Heavier doors require hinges with greater load-bearing capacity. Similarly, the material of the door (solid wood, medium-density fiberboard (MDF), etc.) influences the required hinge strength. Desired functionality, such as soft-close mechanisms, also plays a role. For instance, a heavy solid wood door would necessitate a robust hinge with a soft-close feature to prevent slamming and damage. Lighter MDF doors might suffice with a simpler, less expensive hinge.

Hinge Durability and Longevity

The durability and longevity of your hinges are crucial for long-term kitchen cabinet performance. Factors such as frequency of use and environmental conditions (humidity, temperature fluctuations) affect hinge lifespan. High-quality hinges, made from robust materials like zinc alloy or stainless steel, are more resistant to wear and tear, ensuring a longer service life, even with frequent use. In humid environments, hinges made of stainless steel are preferable to prevent corrosion. Consider the predicted usage frequency – hinges in frequently accessed cabinets will require greater durability than those in less-used areas.

Selection Flowchart for 165-Degree Hinges

The following flowchart guides homeowners through the selection process, considering budget, style, and cabinet type.

↓

Cabinet Type: Full Overlay

↓

Door Weight: Heavy

↓

Blum Aventos HF (or similar high-end hinge)

Budget: Moderate

↓

Cabinet Type: Overlay/Inset

↓

Door Weight: Medium

↓

Hafele Grass Tiomos (or similar mid-range hinge)

Budget: Low

↓

Cabinet Type: Overlay

↓

Door Weight: Light

↓

Liberty 165 Degree Hinge (or similar budget hinge)

Troubleshooting and Maintenance of 165-Degree Hinges

Maintaining your kitchen cabinet hinges ensures smooth operation and extends their lifespan. Understanding common problems and implementing preventative maintenance will keep your cabinets functioning flawlessly for years to come. This section details practical solutions for troubleshooting and maintaining 165-degree hinges, a crucial component in modern kitchen design.

Common Problems and Solutions

Addressing issues promptly prevents minor inconveniences from escalating into costly repairs. The following Artikels frequent problems with 165-degree hinges and their corresponding solutions.

- Problem: Cabinet door sags or is misaligned. This often stems from loose screws or worn hinge components.

Solution: Tighten all screws using a screwdriver. If the sag persists, replace worn hinges. Ensure the screws are securely fastened into the cabinet frame and door. If the door is still misaligned after tightening, slight adjustments to the hinge screws may be necessary (see Hinge Adjustment section below). - Problem: Door binds or sticks when opening or closing. This can be caused by paint buildup, debris, or a warped door.

Solution: Carefully remove any paint buildup from the hinge and its contact points using a putty knife or fine sandpaper. Clean the hinge with a soft cloth and appropriate cleaning solution. Check the door for warping; a warped door may require replacement. If the door is sticking due to friction, lubrication (see Hinge Lubrication section below) can help. - Problem: Hinge mechanism is noisy or creaky. This is often due to lack of lubrication or wear and tear on moving parts.

Solution: Lubricate the hinge using a light machine oil or silicone-based spray lubricant. Apply a small amount to the hinge’s moving parts and gently work the door open and closed several times to distribute the lubricant evenly. Avoid excessive lubrication, which can attract dust and dirt.

Hinge Lubrication

Regular lubrication is crucial for preventing wear and tear and ensuring smooth operation of 165-degree hinges. Neglecting lubrication can lead to increased friction, noise, and premature failure of the hinge mechanism.

Proper lubrication involves selecting the right lubricant and applying it correctly. A light machine oil or a silicone-based spray lubricant is generally recommended. Avoid using heavy greases or oils, as these can attract dust and dirt, potentially worsening the problem. Apply a small amount of lubricant to the hinge’s moving parts, ensuring it penetrates the joints. Work the door open and closed several times to distribute the lubricant effectively.

Hinge Adjustment

Minor misalignments can often be corrected by adjusting the hinge screws. Most 165-degree hinges have adjustment screws that allow for fine-tuning the door’s position. These screws typically control the vertical and horizontal alignment of the door.

To adjust the hinge, use a screwdriver to carefully turn the adjustment screws. Small adjustments can significantly impact the door’s alignment. Always make small adjustments and test the door’s position before making further adjustments. Refer to the hinge manufacturer’s instructions for specific adjustment procedures. Improper adjustment can damage the hinge or the cabinet.

Cleaning and Maintenance

Regular cleaning prevents dirt and debris from accumulating on the hinges and interfering with their smooth operation. Use a soft cloth and a mild cleaning solution to wipe down the hinges periodically. Avoid harsh chemicals or abrasive cleaners, as these can damage the hinge’s finish. Pay particular attention to the hinge’s moving parts, removing any accumulated dust or grime. Regular cleaning, combined with lubrication, will significantly extend the life of your 165-degree hinges.